Integration and planning of production effectively is essential for streamlining business operations. SAP S/4 HANA 2023’s Advanced Production Integration with SAP EWM allows seamless connection between warehouse and production operations to ensure smooth movement of goods and information flow.

This blog focuses on the integration process, providing the steps involved, examples of use and practical tips to implement Advanced Production Integration with SAP EWM to streamline production planning and warehouse management for enhanced efficiency and real-time synchronization.

Table of Contents

Understanding the Manufacturing Scenarios in SAP

Before diving in to integration, it’s essential to understand the different manufacturing processes available within SAP Production Planning (PP):

- Discrete Manufacturing: Ideal for industries such as mechanical engineering and electronics where products can easily be assembled, disassembled and reworked without complex assembly steps being needed.

- Process Manufacturing: Used for batch-oriented processes such as pharmaceuticals, chemicals and food industries.

- Repetitive Manufacturing: This form is more applicable for large-scale and continuous production lines such as those found in automotive or consumer goods industries.

These manufacturing approaches help determine how production planning aligns with warehouse operations.

Why Should I Integrate Advanced Production Integration With SAP EWM?

- Increased Efficiency: Automating warehouse tasks can decrease manual errors and speed up production.

- Real-Time Synchronization: Seamless communication between SAP PP and EWM ensures timely material availability.

- Scalability: Suited for single-order and cross-order production scenarios, but implementation challenges vary according to production scenario. Initial setup must be conducted carefully, while training staff on new processes is also key for success.

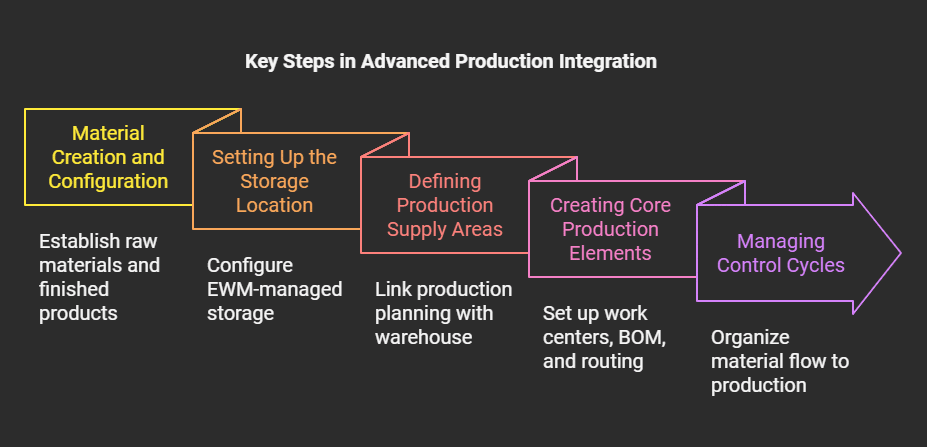

Key Steps in Advanced Production Integration

Material Creation and Configuration

- Create two raw materials with mandatory MRP views. * Define one finished material using both MRP and work scheduling views. 2. Establishing Storage Location

- Create an EWM-managed storage location within your system. * Map it to an actual warehouse or plant within your enterprise structure. 3. Define Production Supply Areas (PSAs) PSAs provide an integral link between production planning and warehouse operations.

- In S/4 HANA: Use transaction PK05 to create PSAs.

In EWM: Define PSAs using the /N/SCWM/PSA attribute through either replication or manual mapping.

Establishing Core Production Elements

- Work Centers: CRO1 can be used to set up work centers. Bill of Materials (BOM): Define the structure of finished products. Routing: Plan out production operations sequence. 5. Administering Control Cycles

Control cycles govern the movement of raw materials toward production: * Single Order: Materials are staged for individual orders. - Cross Order: Materials are staged for multiple production orders.

Integration With EWM

Advanced production integration goes far beyond simple material staging. Here’s how SAP S/4 HANA interacts with EWM for seamless operations:

- Inventory Determination and Removal (ID/RS) Maintain stock determination groups and devise removal strategies to ensure that production will take place using only appropriate stock. This ensures the appropriate stock will be chosen.

- Mapping Order and Item Types This step ensures that warehouse operations meet production needs.

- Warehouse Process Types To define warehouse process types for single order components or cross order components.These settings simplify staging and consumption processes within the warehouse.

Testing the Integration Process

- Generating Production Orders Utilize CO01 to generate production orders. Check BOM, routing, and production version using the master tab.

- Simulating and Executing Material Staging* Simulate material staging using CO02.

Execute and monitor the creation of production material requests (PMRs). - Managing Warehouse Tasks

- Create tasks for single and cross-order components using N/SCWM/STAGE, then confirm these to facilitate stock movements. 4. Goods Issue and Stock Monitoring utilise RF devices to record consumption levels, while consolidating tasks to streamline stock movements.

- Track goods issue postings using MB51.

Real-World Applications of Virtualization.

Case Study: Continuous Production in Electronics An electronics manufacturer used SAP EWM Advanced Production Integration to streamline the production of high-demand products by using cross-order staging to reduce warehouse congestion and improve material availability, allowing continuous production. They experienced significant benefits, including 15% fewer shortages in materials used during production as well as 20% increased production efficiency and and increased visibility of inventory movements across warehouses.

Conclusion

Advanced Production Integration with SAP EWM in S/4 HANA 2023 can transform production planning from an unwieldy, rigid process into an agile one, helping businesses increase operational efficiencies, lower costs, and meet market requirements with precision. By taking advantage of these tools, businesses can enhance operational efficiencies, cut expenses and meet market needs more precisely than before.

Implementing SAP EWM advanced production integration may seem complicated initially, but its long-term benefits more than justify its challenges. Companies looking to remain competitive will find this integration invaluable.

You might also like the below articles.

- Credit management comparison of sap fscm

- SAP EWM

- sap s4hana migration

- GST E invoice

- understanding abap objects

- clean core sap

- SAP interfaces

- Joule ai copilot

- Mastering sap background job processing

- SAP Ewm tcodes a handy guide

- Object-oriented programming in sap abap

- understanding sap license costs

- SAP Datasphere

- industry4.0 with sap

- Condition contract management in sap s4 hana

- Comprehensive guide to go live

- SAP EHS Module

- Power of generative ai in sap

- SAP Joule Comprehensive Guide

- Mastering the dunning process sap

- Creation of chart of accounts in sap fico

- Different roles of an sap consultant

- understanding sap system landscape

- Product costing in sap

- Copa in sap

- subcontracting process in sap mm

- SAP S4hana cloud

- Disaster Recovery in SAP HANA Cloud

- SAP ABAP beginner’s journey

- Year-end activities in sap

- ethical ai development