Today, we’ll go through MTO configuration, which stands for Make to Order situations in SAP SD. Make to Order is very beneficial when the product does not manufacture in advance buts it will manufacture based on customer-specific requirements .e,g high-end vehicles, motorcycles, other luxury cars. Customers order cars with specific requirements such as color & features.

Table of Contents

Introduction of Make-to-Order (MTO)

Make-to-Order (MTO) is a production planning strategy that focuses on producing a finished product in response to a specific sales order. This approach is customer-centric, ensuring products are tailored to specific customer requirements and allowing cost tracking at the sales order level. MTO strategies are suitable for situations where materials are uniquely assigned to specific sales orders, cost tracking is needed at the sales order level, and material master data is set up correctly. There are various MTO strategies, including basic MTO (no specific product structures), advanced MTO (requiring a specific product structure), planning without final assembly, customer stock, and integration with other processes. MTO production ensures that production aligns with actual customer demand and allows for seamless handling of variants and configurations within the MTO framework. Overall, MTO production streamlines the process by producing goods only when a confirmed sales order is received, optimizing resource utilization and cost tracking.

What Is MTO | Make to Order

MTO known as made-to-order is a production approach that allows customers to buy products that are tailored to their individual needs. It’s a manufacturing method in which an item’s production begins only once a customer order has been confirmed.

Make-to-order is used in the following environments:

- Production using specification/requirement of customer.

- Assemble-to-order(ATO)

What is the Make-to-order strategy

- The materials are segregated. This means they are uniquely assigned to specific sales orders.

- Costs must be tracked at the sales order level and not on the material level.

Make to stock process scenarios

We start by creating a sales order in SD and then transferring the requirements to Production planning. Before a production order is generated, the requirements are validated using MRP. Production planning is used to produce this production order. Both shipping and billing take place in SD. Finally, we examine CO’s costs and income.

Make to order Process Flow

Let’s understand the configuration behind make to order process

Material Master preparation for Make to Order scenarios

In the Material Master, There are pre-requisite setting that needs to carry out to process Make-to-order scenarios .In screen Sales, Org 2-Item Category Group is indicated. Incase of MTO with variant configuration item category TAC has item category group 0002

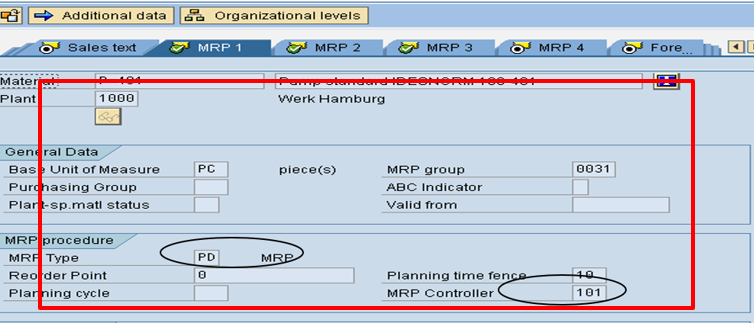

Similarly, In the MRP1 screen, MRP 1-MRP Type and MRP Controller must be mentioned as below as per the SAP Standard.

Now in MRP 3-Strategy group must be mentioned

Assembly order

Once Master data has been set up. Now we can start creating a Sales order, to create a sales order follow the SAP easy access menu.

SAP Easy Access -> Logistics -> Sales and Distribution -> Sales -> Order -> Create (VA01)

Checking requirement MRP

In these steps, Material has been the plan for the Make to order strategy, hence we need to check whether the requirement has transferred to MRP.

Logistics -> Production ->MRP -> Evaluations ->Stock/Requirements List (MD04)

Requirements Planning

Requirements planning in (MRP) is a manufacturing process control that includes production planning, scheduling, and stock requirement.

SAP Easy Access ->Logistics -> Production ->MRP ->Planning -> Single-Item, Multi-Level (MD02)

Convert Planned Order to Production Order

Once the requirement has been captured we need to convert the Planned order to a production order with the below steps.

SAP Easy Access ->Logistics -> Production ->MRP -> Evaluations ->Stock /Requirement list (MD04)

Now Displaying the details of planned order in MD04, Choose -> Prod. Order ( Convert planned order into production order)

The next steps would be to release the order, choose the flag. schedule the order, choose the next icon . Save-Prod. Order is created

Withdrawing the Material for the Production Order

System creates a reservation for the relevant material components when you make a production order. Within the reservation, each material component of the order is assigned a unique item number. Only after the operation to which the reserved materials are assigned in the order has been released may you retrieve them from the warehouse.

SAP Easy Access ->Logistics ->Materials Management ->Inventory Management ->Goods Movement ->Goods Issue (MB1A).Enter the Prod. Order created

Choose “Adopt + Details”.Save.

Confirming Production Order

Now next will be confirmation of ticket for the production order,to perform confirmation

SAP Easy Access ->Logistics à Production ->Production Control -> Confirmation -> Enter->For Operation -> Time Ticket (CO11N)

Goods Receipt against Sales Order

now receipt of goods in relation to a sales order using transaction code mb31 & movement Type 101

Stock overview

Check stock overview using Transaction code MMBE which Indicates material against Sales Order Stock.

Create Delivery

The schedule line will be confirmed in the sales order, therefore we will allow creating subsequent delivery

SAP Easy Access -> Logistics -> Sales and Distribution -> Shipping and Transportation -> Outbound Delivery ->Create (VL01N)

Create Billing

Once post good issue has been posted with reference to delivery

SAP Easy Access -> Logistics -> Sales and Distribution -> Billing -> Billing Document -> Create (VF01)

A billing document will be created, Which end of the complete cycle.

What is the distinction between Make to stock & Make to Order in sap

Which is better MTO or MTS?

There is no clear winner between MTS & MTO, Those two different approaches followed in production planning & optimization based on business needs

We hope this post has helped you comprehend the make-to-stock process flow…. Good luck with your studies…!! Please check out articles

- ERP

- Enterprise structure

- SAP Standard reports

- SD Determination

- SAP WM Vs SAP EWM

- sap ariba procurement

- sap fiori app library

- SAP SD Interview Questions for Freshers and Experienced

Looking for good books to read ? try this one