Table of Contents

Introduction to SAP EWM

Modern warehouses and logistics systems are rather complicated and require great management to guarantee seamless operations. Among such strong management systems, SAP Extended Warehouse Management (EWM) is one of those that helps companies to very successfully monitor the inventory levels in warehouses and product flow. This guarantees seamless incoming and outbound operations.

With strategic positioning of storage spaces and an exact list of received items and others, SAP EWM offers strong assistance for warehouse operations that differ beyond taking, stocking, and shipping of goods and efficiently arranging such procedures. Other systems have rather different flex structures that allow them to offer appropriate monitoring and management of complex warehouse operations. flawless and in great running order.

Key Differences Between SAP EWM and SAP WM

SAP EWM and SAP Warehouse Management (WM) are parts of the SAP Supply Chain Management portfolio, even though SAP EWM provides more advanced features. The following occurs:

- Improved Capabilities: EWM supports warehouse operations, including building custom work centers, picking, putting away, and managing radio-frequency devices (RF framework). More exact control over warehouse operations comes from this adaptability in layout.

- EWM’s labor management tools help companies to effectively allocate jobs and plan, hence boosting production.

- SAP EWM maximizes the organization of products by letting the development of new features like activity zones and enhanced storage concepts, enhancing the general efficiency.

EWM offers necessary tools to fully handle sophisticated warehouse operations and acts as an upgrade to SAP WM.

Features and Functions of SAP EWM

Key elements abound in SAP EWM that simplify warehouse management. Among these aspects are:

- Control Over Warehouse Activities: It enables management of storage bins, processing of several picking techniques, and posting of product receipts, among other important warehouse operations.

- Alerts for Critical Changes: Alerts can be configured to signal data changes, including goods receipts, therefore enabling managers to respond early on to problems.

- EWM helps mixed handling units to deconsolidate and optimizes goods arrangement by means of slotting procedures.

- Effective labor time planning and resource management will help warehouse operations to be much more efficient.

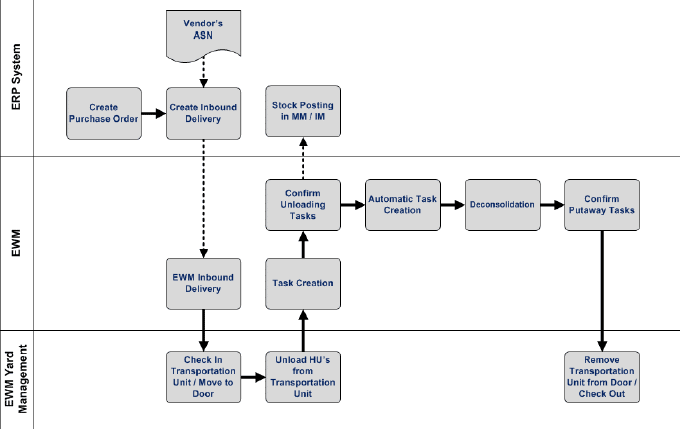

EWM also provides cross-docking features to assist in the movement of transportation handling facilities throughout several distribution hubs. Using these capabilities can help businesses match their warehouse activities with strategic logistics objectives.

Key Features and Functional Areas of SAP EWM

SAP EWM consists of several important characteristics meant to simplify warehouse operations:

- SAP EWM provides two kinds of storage controls: layout-oriented and process-oriented. While layout-oriented storage control allows stock movements over several intermediate points, including conveyor segments, process-oriented storage control helps establish the sequence of process steps—e.g., receiving, deconsolidation, and put away.

- Through RF (Radio Frequency) processing and task interleaving, SAP EWM helps to assign effective tasks to workers depending on their present location, therefore lowering travel times.

- EWM supports cycle counting, zero stock checks, and inventory sampling among several inventory counting techniques. Min/max-based replenishment, among other replenishment techniques, helps to preserve ideal stock levels.

Deployment Options in SAP EWM

Businesses wishing to use SAP EWM have several deployment choices at hand. The main means of deployment are as follows:

- Installed on a stand-alone SAP SCM server, EWM on SCM Server enables it to operate autonomously yet connects with other SCM components.

- Integrated inside SAP ERP, EWM can also run on an ERP server using current ERP capabilities as a reasonably affordable deployment method.

- Large companies which want to run EWM independently with flawless integration to ERP and other systems and demand the best performance will find this option appropriate.

The size of the company and the complexity of its supply chain will determine the suitable deployment strategy.

Key Organizational Units in SAP EWM

To effectively run operations, SAP EWM arranges warehouses hierarchically into multiple organizational divisions. These divisions are summarized here:

- The highest level of the warehouse structure, which arranges all kind of storage inside the warehouse, is the warehouse number.

- Storage Type: Indicates several warehouse portions including high-rack storage, picking sections, etc.

- The smallest component in the construction that precisely marks the placement of products is a storage bin. Good bin management guarantees correct inventory tracking and seamless goods transportation.

- Activity Areas: These show groups of storage bins according to the kind of activity (such as putaway or picking). By grouping bins depending on warehouse activities, activity areas improve efficiency.

Knowing these units guarantees efficient storage and faster retrieval of products, so helping to ensure the optimal planning and supervision of warehouse operations.

Advanced Features in SAP EWM

These extra sophisticated tools of SAP EWM satisfy complicated warehousing needs:

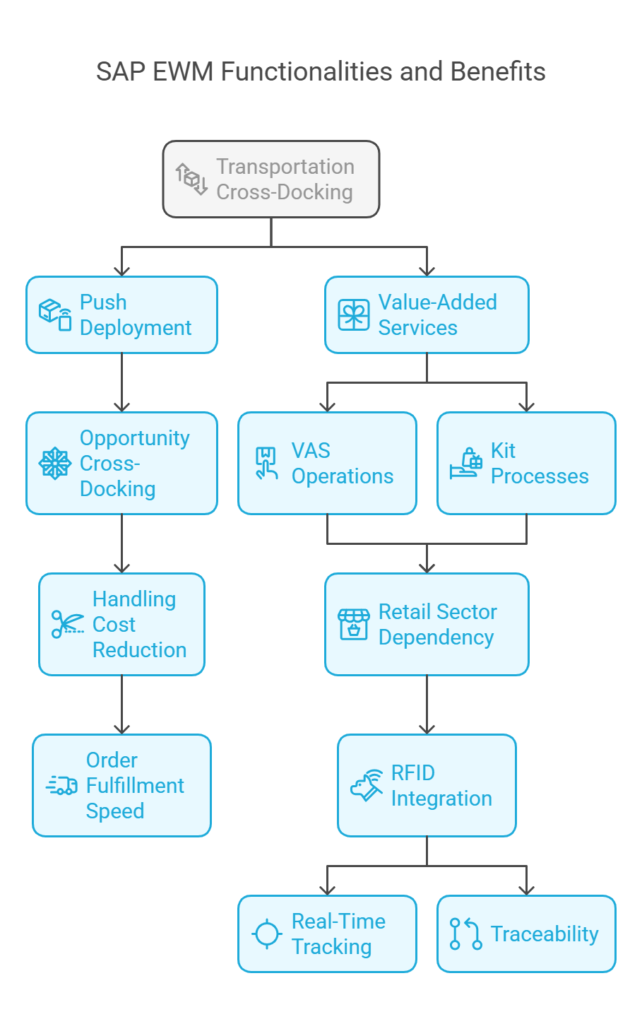

- EWM enables not just Transportation Cross-Docking but also Push Deployment and Opportunity Cross-Docking. This suggests that warehouses help more in lowering handling costs and speeding order fulfillment times.

- EWM offers value added services include VAS operations such as packing, price tagging, and labelling as well as kit processes such as bundling items. Retail and manufacturing sectors depend on these abilities absolutely.

- RFID Integration: For RFID applications including vehicle check-in, reception, location movements, and vehicle check-out, SAP EWM interfaces with the SAP Auto-ID Infrastructure (AII). This improves real-time tracking and traceability still more. These extra sophisticated tools of SAP EWM satisfy complicated warehousing needs:

- EWM enables not just Transportation Cross-Docking but also Push Deployment and Opportunity Cross-Docking. This suggests that warehouses help more in lowering handling costs and speeding order fulfillment times.

- EWM offers value-added services including VAS operations such as packing, price tagging, and labeling, as well as kit processes such as bundling items. Retail and manufacturing sectors depend on these abilities absolutely.

- RFID Integration: For RFID applications including vehicle check-in, reception, location movements, and vehicle check-out, SAP EWM interfaces with the SAP Auto-ID Infrastructure (AII). This improves real-time tracking and traceability still more.

Case Studies and Real-World Implementations

Many businesses have effectively used SAP EWM to simplify their warehouse operations:

Implement SAP EWM across North American distribution centers to handle internal movements, inbound processing, outbound logistics. The organization gained better awareness and control over all warehouse operations by means of thorough integration.

Following expansion, Kimberly-Clark Healthcare applied SAP EWM to handle distribution and inventory control processes. The initiative aimed to improve handling of controlled product lines by combining EWM with batch traceability, therefore enhancing transparency and efficiency.

Among Mexico’s biggest consumer stores, Liverpool Department Stores used SAP EWM to assist its multichannel activities at several distribution hubs. Their decision was much influenced by the system’s stability, strong connection with SAP solutions, and scalability flexibility to enable future expansion.

Conclusion

SAP EWM provides the warehouse operating tools and features to keep functioning smoothly with its fast-changing supply chain management. It goes further than the basic warehouse management system and provides high-level functionalities, such as labor management, slotting, and resource optimization.

Companies which eagerly await the transformation of warehouse operations can apply SAP EWM for better inventory control, low running costs, and more efficiency. The feature of cross-docking and integrated task management allows companies to improve productivity and attain their logistics goals with higher accuracy and agility.

What is SAP EWM?

Comprising a complete warehouse management system, SAP Extended Warehouse Management (EWM) offers adaptable, automated support for handling different product movements and inventory control in your warehouse.

SAP EWM interacts with SAP S/4HANA in what manner?

Integration of SAP EWM with SAP S/4HANA improves warehouse management capacity. Real-time data interchange and enhanced warehouse operations’ efficiency made possible by this integration help to explain why

What distinguishes SAP EWM most importantly

Inventory management, warehouse order generation, resource management, labor management, and advanced shipping and receiving systems define SAP EWM most importantly.

Does SAP EWM support intricate warehouse operations

SAP EWM is made to manage complicated warehouse operations including value-added services, wave management, and cross-docking.

For large-scale warehouses is SAP EWM appropriate

SAP EWM can effectively manage massive numbers of transactions and big stocks, so it is appropriate for big-scale warehouses.

Using SAP EWM has advantages what ones?

Using SAP EWM has benefits in inventory accuracy, warehouse space use, labor productivity, and customer service among other areas.

In what ways may SAP EWM assist with warehouse automation?

By use of conveyor systems, automated storage and retrieval systems (ASRS), and other warehouse automation technologies, SAP EWM facilitates warehouse automation.

How might SAP EWM help with supply chain management?

SAP EWM guarantees effective warehouse operations, lowers lead times, and increases general supply chain visibility, thereby playing a vital part in supply chain management.

Is SAP EWM able to be tailored to fit certain company needs

By means of configuration and additions, SAP EWM can be tailored to satisfy particular business needs.

Which SAP EWM deployment choice exists

SAP EWM can be implemented either embedded inside SAP S/4HANA or as a distributed system.

You might also like the below articles.

- sap project intelligence network

- advanced production integration with sap ewm

- Credit management comparison of sap fscm

- SAP EWM

- sap s4hana migration

- GST E invoice

- understanding abap objects

- clean core sap

- SAP interfaces

- Joule ai copilot

- Mastering sap background job processing

- SAP Ewm tcodes a handy guide

- Object-oriented programming in sap abap

- understanding sap license costs

- SAP Datasphere

- industry4.0 with sap

- Condition contract management in sap s4 hana

- Comprehensive guide to go live

- SAP EHS Module

- Power of generative ai in sap

- SAP Joule Comprehensive Guide

- Mastering the dunning process sap

- Creation of chart of accounts in sap fico

- Different roles of an sap consultant

- understanding sap system landscape

- Product costing in sap

- Copa in sap

- subcontracting process in sap mm

- SAP S4hana cloud

- Disaster Recovery in SAP HANA Cloud

- SAP ABAP beginner’s journey

- Year-end activities in sap

- ethical ai development